Next Generation Supply Chain Model

Responding to digital supply chain disruption

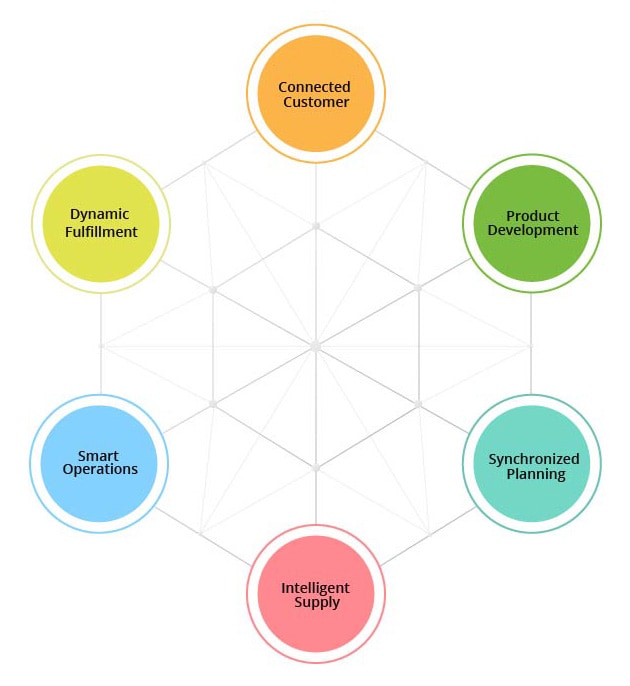

Digital capabilities are disrupting the traditional supply chain operations reference (SCOR) model. A rapidly evolving landscape brings new questions regarding the nature of more complex and tightly integrated supply networks. These dynamic, interconnected systems concurrently plan, execute, and enable digital supply chains. Now, the next-generation supply chain model is here—the digital capabilities model for supply networks.

What challenges are facing supply chain operations?

Complicating an already intensely competitive market, pressures on the world’s supply chain leaders are escalating. From our 2019 supply chain digital and analytics survey, we learned that supply chain businesses identify digital and analytics as a top priority but do not necessarily show ownership of the strategic investment.

In fact, seventy-six percent of respondents said developing digital and analytics capabilities was most important/very important to delivering the overall supply chain strategy. But only 56 percent of respondents indicated they invest $5 million or less in digital and analytics capability development annually.

Meanwhile, day in and day out, linear supply chains continue to be plagued with the intrinsic volatility and inefficiency commonly characterized as the bull whip effect. Addressing the root cause issues that generate this intrinsic behavior requires a paradigm shift in how we design and operate supply networks.

Finally, functional silos and misaligned incentives in organizations can create planning and execution challenges. These strategic issues can be addressed if companies start to transform their linear supply chain into a concurrent network by leveraging digital technologies and capabilities. Now more than ever, it’s critical to leverage an updated supply network model with digital capabilities embedded so it can evolve as the guiding supply chain model in the digital age.

Learn how you can use DCM to plan your digital supply network transformation

The Deloitte and ASCM collaboration: An evolving framework

Digital technologies and capabilities are ushering in a new era: Industry 4.0, the fourth industrial revolution. Advances in artificial intelligence (AI), the Internet of Things (IoT), machine learning, robotics, additive manufacturing, and advanced analytics are fueling innovation. Embedded sensors applied in new ways speed the convergence of the physical and digital worlds. These rapidly evolving forces enable the transformation of traditional, linear supply chains into connected, intelligent, scalable, customizable, and nimble digital supply networks.

But in preparation for Industry 5.0, in which humans will work side by side with robots to deliver value-added tasks, enabling supply chain models must also flex and evolve. That’s what the new Digital Capabilities Model for Supply networks is all about. It’s a new supply chain framework that incorporates emerging drivers of success.

In response to the digital era, Deloitte and the Association for Supply Chain Management are releasing a new standard reference model for supply networks management to help businesses and non-profits develop these capabilities to increase efficiency, drive results, and innovatively enhance performance. Deloitte and ASCM will incrementally develop and release components of the model over a five-year period.

Digital Capabilities Model placemat

Principles of the digital capabilities model for supply networks

The model will represent capabilities and their interdependencies that transcend physical-digital boundaries and include people, processes, and technologies needed to break through traditional organizational silo’s and be competitive in the digital age.

The model will span supply chain functions to achieve enterprise level optimization, aligning planning and execution in collaboration with customers, suppliers, and internal facilities. It will detail how to explicitly leverage established and emerging digital enablement, from IoT and sensors, to the application of data science, machine learning and artificial intelligence, and lights out supply network planning and execution functions.

Start your supply chain model transformation

Are you ready to take the first step on your digital supply chain journey? With our solutions, you can build an ecosystem that connects and automates your value chain.

Digital Readiness Assessment. Take a 10-minute assessment to learn how your organization’s digital readiness capabilities measure up.

The Deloitte Greenhouse® Corporate Innovation Lab. Break down barriers and accelerate meaningful results through one- to two-day interactive sessions tailored to address specific business challenges. The result? Behavioral science, design thinking, and strategy converge to help you solve your toughest business challenges.

- Immerse and inform: Immerse yourself in the details of digital transformation and disruptive technologies that impact the value chain. Inform yourself with a new business and digital transformation strategy, and in-flight initiatives.

- Explore the art of the possible: Explore the importance of integration between operating technology and information technology (including sensor technology). You’ll learn how data and tech architecture are related to the implementation of new use cases. Plus, you’ll discover a selection of value creating use cases that are relevant to your digital transformation goals.

- Design the path forward: Design a high-level implementation roadmap by prioritizing ideas and business needs. You’ll review case studies of Deloitte’s digital transformation experiences to help inform your strategy. Then, we’ll help conduct an interactive session where potential opportunities are identified and documented. Finally, take part in a discussion on the role people and culture play in the success of transformative change.

ASCM Transformation Learning Programs: Accelerate your key supply chain initiatives with a proven learning approach. Build organizational capabilities by coaching and mentoring your leaders through a 12-week program across five phases.

- Engage: Engage the team to assess the need for supply chain improvement and gain executive sponsorship

- Define: Capture strategic business priorities, define business goals and set scope of assessment

- Analyze: Implement SCORmark, diagnose root causes, recommend improvements, estimate value proposition

- Plan: Plan the portfolio of improvement programs and affirm value proposition versus strategic priorities

- Launch: Confirm value proposition, sponsorship and resources, and launch implementation projects

NEW to the Digital Capabilities Model (DCM) for Supply Networks

We are excited to announce the following enhancements to the Model:

- A metrics library linking DCM metrics across the digital supply network and showing the connection of SCOR to help identify metrics that matter most to you.

- Updated mapping of Level 2 connections (L2-L2, both incoming & outgoing) which includes frequency, impact, and connection rationale to highlight the connectivity of a dynamic network.

- Digital chords are defined as a set of capabilities connected in sequence to address the end-to-end impact of a specific business challenge or enable an integrated business function. Digital chords help define the connections within a digital supply network by representing seamlessly connected streams of information and digital twins that are enabled through people, processes, and technologies.

- Enhanced content and updates to Synchronized Planning, Product Development and Intelligent Supply capabilities.

- FAQs to help answer your questions and provide definitions for key terms used in the model.

- “About DCM” page that provides background on the Digital Capabilities Model.

Deloitte and ASCM unveil digital capabilities model for supply networks

Read what others are saying

- ASCM and Deloitte roll out Digital Capabilities Model for Supply Networks, September 17, 2019, Logistics Management

- Deloitte, ASCM Push Digital Supply Networks—Not Chains, September 17, 2019, Sourcing Journal

- Afternoon Coffee: SolutionMap updates quarterly rankings; new Deloitte-ASCM digital tool; Cargill expanding in China, September 17, 2019, Spend Matters

- Perspectives On The ASCM And Deloitte Joint Announcement Of A Supply Chain Digital Capabilities Model, September 25, 2019, Supply Chain Matters

- Building a DSN? There’s a New Road Map for That, September 29, 2019, The Wall Street Journal – CIO Journal