From vision to value: A road map for enterprise transformation in manufacturing with agentic AI

Deloitte explores how manufacturers can harness agentic AI to help reshape their business and create value across their organizations

Patricia Henderson

Ajay Chavali

Lindsey Berckman

Kate Hardin

John Morehouse

Key takeaways

- Agentic AI has the potential to transform the way manufacturers operate, and industry adoption could grow considerably over the next few years.

- Agentic AI can help add substantial value across a manufacturing firm, from the back office and production floor to engineering, supply chain management, sales, and aftermarket services.

- To achieve a transformative future with agentic AI, manufacturers should take an “understand scale first” approach that includes developing a prioritized agentic AI road map and then starting with the solutions that offer the highest potential value at scale.

- An “understand scale first” approach considers key factors such as the cost, talent, data, technology, governance, and workflow transformation necessary at scale, and it could be essential to move from pilots to successful implementation.

- Fostering a culture of transparency and collaboration can help identify high-value opportunities for agentic AI implementation and accelerate adoption by building worker awareness of how it could improve their roles.

Agentic artificial intelligence has the potential to transform how companies operate in the next few years, and manufacturers seem to have taken notice. According to a survey conducted by the Manufacturing Leadership Council in early 2025, while only 6% of surveyed manufacturers are currently using agentic AI, 24% expect to be using it in just two years—a fourfold increase.1 Deloitte’s recent State of Generative AI in the Enterprise report indicates that 26% of surveyed companies are exploring agentic AI to a large or very large extent.2 A Gartner report also forecasts that 33% of enterprise software will embed agentic AI by 2028—up from less than 1% in 2024—with the ability to make about 15% of routine work decisions autonomously.3

In this article, we explore the future of the manufacturing firm with agentic AI and multiagent systems, which we refer to collectively as agentic AI (see “Agentic AI tools act autonomously to help manufacturers tackle complex tasks”) and the steps companies might consider now to prepare for this future.

Agentic AI tools act autonomously to help manufacturers tackle complex tasks

Agentic AI refers to autonomous generative AI agents that possess “agency”—the ability to both act and choose actions to take—which enables them to independently complete complex tasks and achieve human-defined objectives with minimal or no supervision.4 Multiagent systems consist of multiple AI agents completing specific objectives and collaborating to accomplish sophisticated workflows.5

Gen AI chatbots and gen AI agents are both powered by large language models (LLMs) at their core. However, gen AI agents add additional capabilities, including short- and long-term memory; access to a wide variety of tools; and the ability to reason, plan, and act autonomously.6 For example, a gen AI chatbot can assist a technician in performing preventative maintenance on a computer numerical control (CNC) machine tool by providing information and relevant instructions from manuals in response to a series of prompts. An agentic AI tool such as a multiagent system might take a simple prompt from the technician, such as, “I want to perform preventative maintenance on CNC machine X,” and leverage several agents and an agent orchestrator to interface with multiple systems to help the technician complete the task. For instance, the agentic AI tool could autonomously provide a tailored set of step-by-step instructions, notify a production scheduling agent that the machine is down, adjust instructions as the technician completes the steps or if sensors detect anomalies, and then automatically log completion data.

In general, due to its ability to act autonomously, agentic AI can be an important new tool to help manage the complexity that manufacturers can face throughout the organization. It may also serve as an important building block for the future of automation in the industry, including robotics achieving increasing degrees of agency, or workers having enhanced access to process and equipment trend information on industrial tablets as agentic AI helps to break down data silos.7

How manufacturers can leverage the business value offered by agentic AI

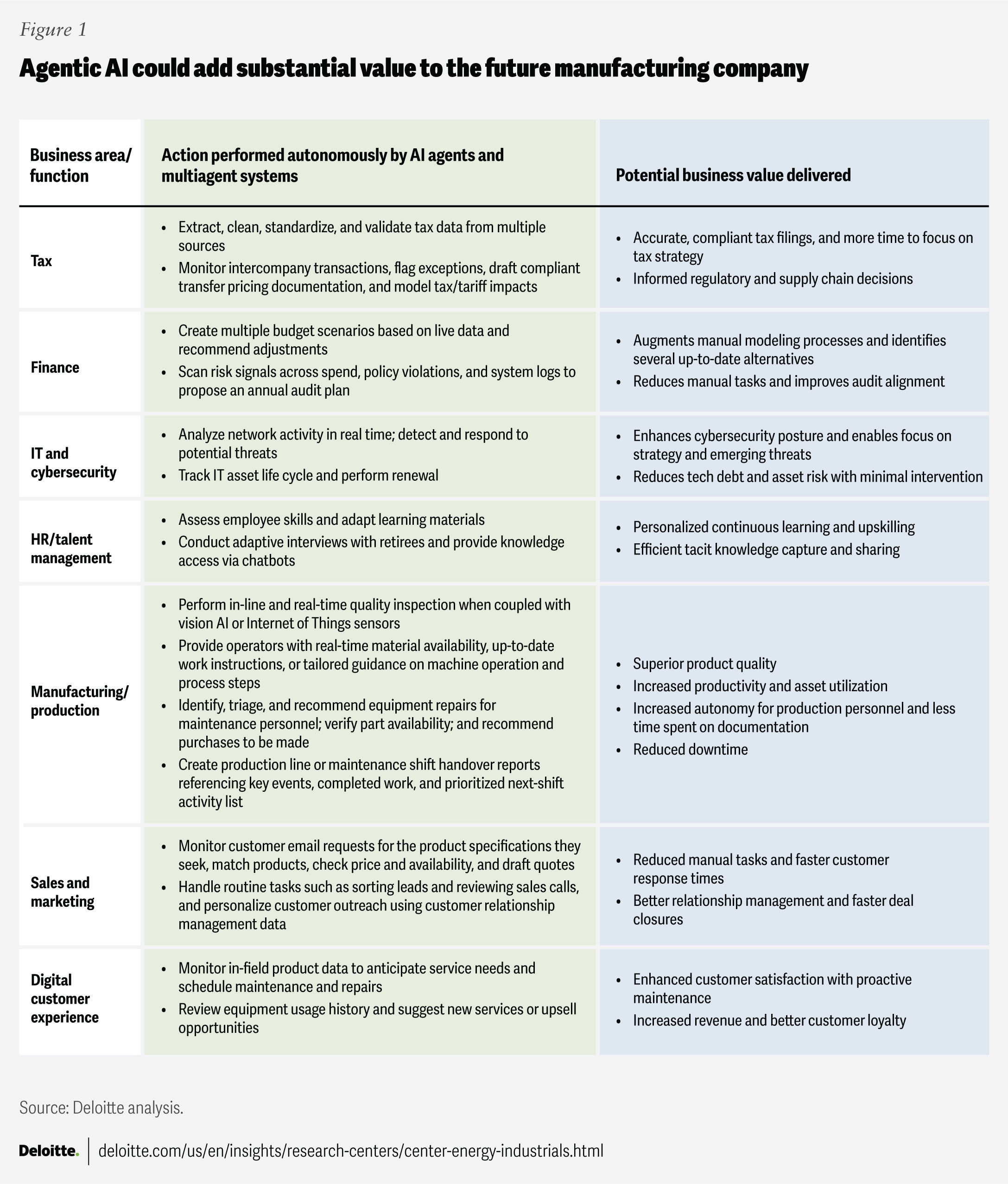

The power of agentic AI is due in part to its ability to work independently alongside people, as a teammate,8 to automate certain tasks. This can augment human capabilities, help workers achieve objectives more efficiently, and free up their time to focus on higher-value and potentially more rewarding activities. Agentic AI use cases have the potential to add substantial value across a manufacturing company, from the back office and production floor to the front office (figure 1).

However, agentic AI’s automation of certain tasks not only lends itself to augmenting human capabilities; it could also enable new—and potentially transformative—outcomes. For instance, an ongoing challenge for manufacturers is siloed data housed in or generated by a variety of new and legacy information technology (IT) and operational technology (OT) systems throughout the enterprise.9 The ability of agentic AI to take autonomous action across multiple internal and external systems of record could enable companies to capture the value that can often be lost in the handoff between disparate systems, such as enterprise resource planning, manufacturing execution systems, product life cycle management, customer relationship management, and supply chain management platforms. This is likely to help generate significant value at the heart of the business, as illustrated in the potential use cases below.

Identify alternate sourcing in response to ongoing supply chain volatility

Agentic AI systems could be employed to proactively minimize part shortages and costs due to supply chain disruptions that can be caused by a variety of factors.10

How it can work

AI agents could be deployed to monitor external sources in real time, such as news sites, weather data, and information from logistics providers to identify potential sources of risk or disruption. When an issue is detected, the system could:

- Analyze “should cost”11 versus delay trade-offs of rerouting orders to previously identified alternate suppliers.

- Ask procurement managers if they would like the system to begin contract negotiations based on the results

- Share data with an agentic AI production system that can adjust production schedules based on changes in part delivery time

- Update customers on any changes in product delivery dates

Design customer-centric products faster

A product design engineer could work alongside an agentic AI system to create design concepts for products that may better meet customer needs while also accelerating new product introduction.

How it can work

A design engineer tasked with designing a new seat for a tractor, for example, could input key requirements, such as the typical weight the seat must support, and constraints, such as materials and maximum dimensions. The agentic AI design system could:

- Gather customer usage data from remote product monitoring systems and common maintenance or repair issues from online customer portals and dealer service systems.

- Generate several design options according to the inputs and data gathered.

- Evaluate each based on design and functionality requirements.

- Continue iterating until the engineer has a range of potentially viable designs that can be further refined and developed.

Autonomously generate and update work instructions to maximize quality and uptime

An agentic AI solution could be deployed to automatically generate and maintain work instructions for the shop floor, helping to ensure production line operators always work from the latest version, minimizing the potential for confusion, errors, and production delays.

How it can work

- Agents access data from computer-aided design files, the bill of materials, and even notes about quality issues that assembly workers and first-line supervisors have experienced over the years to autonomously generate work instructions for a manufacturing engineer to review and approve.

- Agentic AI automatically revises work instructions when engineering changes are made to a part or assembly and requests approval to push the updates to the production floor.

Reconfigure production lines to maximize uptime in the face of disruptions

AI agents could also be deployed to autonomously reconfigure production lines in response to disruptions. Such a tool could provide companies with the agility and resilience they need to consistently deliver to their customers during a time of trade tensions, supply chain volatility,12 and challenges with finding skilled workers.13

How it can work

- AI agents monitor supply chain data, worker skills and availability, inventory levels, equipment status, and customer demand.

- If a disruption occurs, such as a part shortage or machine failure in the factory, the agentic AI system autonomously generates a revised production schedule that can reroute workers to other assembly tasks based on skill sets, production demand, and equipment and part availability, and requests approval from a production planner to implement the change.

Enhance aftermarket services to generate more revenue

Agentic AI could revolutionize customer experience, drive customer loyalty, and increase revenue from aftermarket services, which already provide twice the margins of product sales.14

How it can work

A heavy equipment customer, for example, could initiate a chat with a virtual assistant in the manufacturer’s online customer portal to get help with equipment repair. An agentic aftermarket system could:

- Propose a step-by-step repair solution for the customer to review, suggest the parts required to complete the repair, the dealer location of those parts, and offer to place the order.

- Identify potential service schedule openings at nearby dealerships, provide an estimated completion date, and offer to schedule an appointment if the customer prefers that the dealer complete the repair.

How manufacturers can prepare today for a future with agentic AI

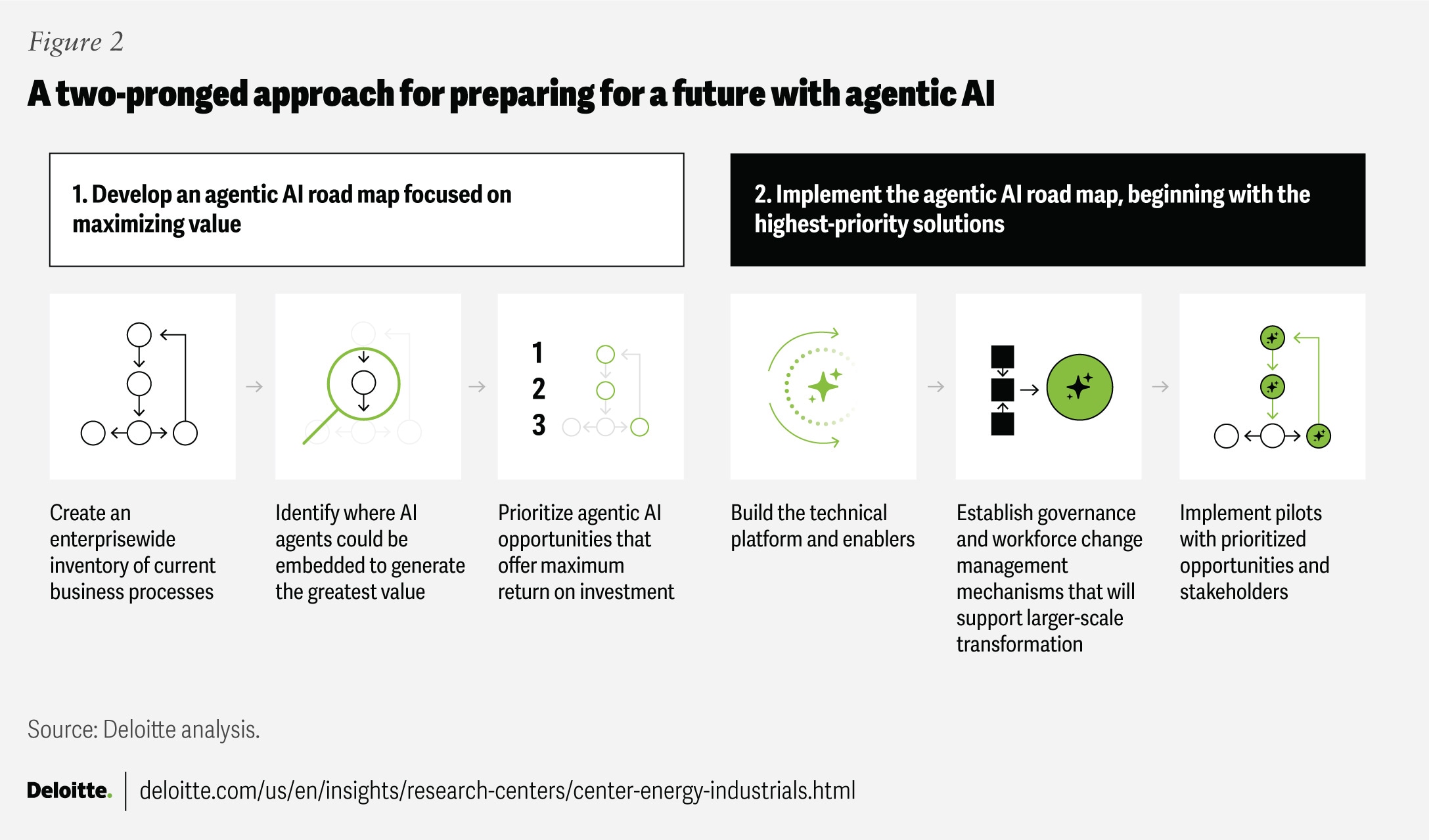

Given the potential value it can generate, an agentic AI–enabled enterprise could become table stakes for how manufacturing companies compete in the future. Manufacturers can start with a two-pronged approach and several key steps to realize their transformative future with agentic AI (figure 2). Regardless of a company’s current position on the AI- or tech-adoption curve, several steps in this approach can also help them prepare for AI and gen AI adoption today while also laying the foundation for scaling into fully agentic decision-making AI in the future.

1. Develop a prioritized agentic AI road map focused on maximizing value

Manufacturers can begin their journey by creating a prioritized road map for how they plan to implement agentic AI solutions that will deliver maximum value.

Create an enterprisewide inventory of current business processes

A detailed enterprisewide inventory of business processes can serve as the foundational map for identifying where agentic AI may deliver the most value. To create it, company and technology leaders can work together to:

- Create current-state process or flow diagrams to highlight inputs and outputs, key metrics, dependencies, bottlenecks, and potential areas for improvement.

- Catalog the key data sources and systems that support each process since the quality, accessibility, and structure of this data can impact the feasibility and effectiveness of agentic AI solutions.

- Identify and engage business process owners and stakeholders, including workers and key business users, to glean important details and insights about the process and common challenges.

Identify where AI agents could be embedded to generate the greatest value

Close collaboration among leadership, technology teams, process owners, and stakeholders will be a key component of identifying where AI agents can generate the greatest value. Rather than a top-down mandate from leadership, the identification of opportunities to maximize value should be a collaborative effort. It should leverage the expertise of the process experts—process owners and stakeholders—to share their pain points and potential areas for substantial improvement. It should also draw upon the knowledge of the technology experts who can share how agentic AI has been successfully used by other companies to generate value within the business function or domain. Leadership can help pressure-test ideas against broader business outcomes and consider how agents can be deployed to help improve key metrics such as margins, customer engagement, and market share.15

However, this collaborative effort should look beyond incremental efficiency gains that could come from improving existing processes. In some cases, workflows may need to be redesigned to unlock agentic AI’s full potential. This may involve rethinking how and when process steps are performed, how decisions are made, how information flows, and ultimately, how value is delivered to customers and stakeholders. Leadership giving process owners and stakeholders a seat at the table may not only add significant value for how to best redesign business processes, but also build awareness about how the technology could address their pain points and improve workflows, potentially accelerating its adoption.

Prioritize agentic AI opportunities that offer maximum return on investment at scale

The final step in creating an agentic AI implementation road map is to establish clear priorities—that is, choosing which investment opportunities to tackle now versus in the future. Manufacturers should focus on opportunities with the potential to deliver maximum value to their core business and return on investment (ROI) at scale. This means that prioritization should also consider all resources necessary to implement the agentic AI solution and those that will be needed to support and maintain it at scale, including costs, talent, data, and technology. A thorough and data-backed approach that considers these important factors could be essential to avoid investments in pilots that may not scale effectively, or perhaps not deliver the expected value.16 This “understand scale first” domain-focused approach can also help to concentrate resources on the highest-value opportunities.

“A thorough and data-backed approach that considers key factors such as the cost, talent, data, and technology to achieve at-scale success of agentic AI solutions could be essential to avoid investments in pilots that may not scale effectively, or perhaps not deliver the expected value.”

The successful implementation of agentic AI solutions will likely require skills and knowledge in AI and data, paired with deep manufacturing or functional expertise.17 Once in place, agentic AI solutions will require human oversight, making critical thinking and business knowledge vital to evaluate AI outputs. In the short term, companies may want to look for high-value opportunities where high-quality, accessible, and structured data already exists, or areas where data can be most easily transformed.18 And manufacturers should also consider the potential technology investment that may be needed to support each agentic AI solution, keeping in mind that a hybrid strategy—combining tailored AI development with existing platforms—may help to reduce the required investment and complexity.19

2. Implement the agentic AI road map, beginning with the highest-priority solutions

With a prioritized agentic AI road map in place, companies can shift their focus toward execution. Implementing the road map requires a structured approach that balances technology development, well-managed organizational change, and focused iteration to successfully move from pilots to at-scale value realization.

Build the technical platform and enablers

Agentic AI success generally begins with designing a robust platform framework and architecture tailored to the unique requirements of AI agents. Manufacturers should identify and select the appropriate AI and data platforms, vendors, and hardware infrastructure—often leveraging hybrid cloud solutions—to help ensure the required performance, scalability, and cost-effectiveness.20 Careful vendor selection and architectural planning are critical to avoid technological lock-in and to maintain flexibility as the technology evolves.

As more software providers offer agentic AI solutions, manufacturers should compare the agentic AI capabilities of their existing platforms to those offered by potential new providers. Considerations include maximizing current interoperability and future integration capabilities with internal and external systems, governance and security features, and multiagent orchestration and agent customization capabilities. Companies should also keep in mind that utilizing agentic solutions in existing platforms could provide quick wins, but investments in new platforms may be necessary to maximize ROI and reach enterprise scale down the road.

Developing a comprehensive data architecture is also important. It should be built around three core elements that can collectively provide the data backbone required for advanced agentic AI applications across the enterprise.

- Strong data governance practices are essential to ensure data quality, security, compliance, and trust, when accessing and using potentially sensitive enterprise data, while implementing a centralized data strategy can streamline acquisition and minimize redundancy.21

- A common data ontology can standardize data and enhance interpretation and interoperability between systems and functions.22

- Knowledge graphs can help unlock deeper insights by connecting disparate data sources and contextualizing information for AI agents.23

Close collaboration between technology teams and business stakeholders will be important to help ensure that platform solutions are aligned with operational needs and strategic objectives. Joint development and deployment can foster buy-in, accelerate adoption, and help identify potential issues early in the process.

Establish governance and workforce change management mechanisms that will support larger-scale transformation

The self-directed behavior of agentic AI could raise new concerns about accountability, bias, privacy, and regulation, making new governance models and updated change management essential when deploying these systems in real-world settings. Implementing operational guardrails for security and privacy will be important to protect sensitive data and help ensure regulatory compliance.24 Effective governance can help to ensure that AI initiatives also align with business goals and ethical standards. This includes defining clear roles and responsibilities, setting policies for AI use and oversight, and establishing processes for monitoring performance and managing risk.

According to a recent Deloitte report, organizations that invest in building human capabilities are almost twice as likely to have employees who find their work meaningful and to achieve superior business outcomes.

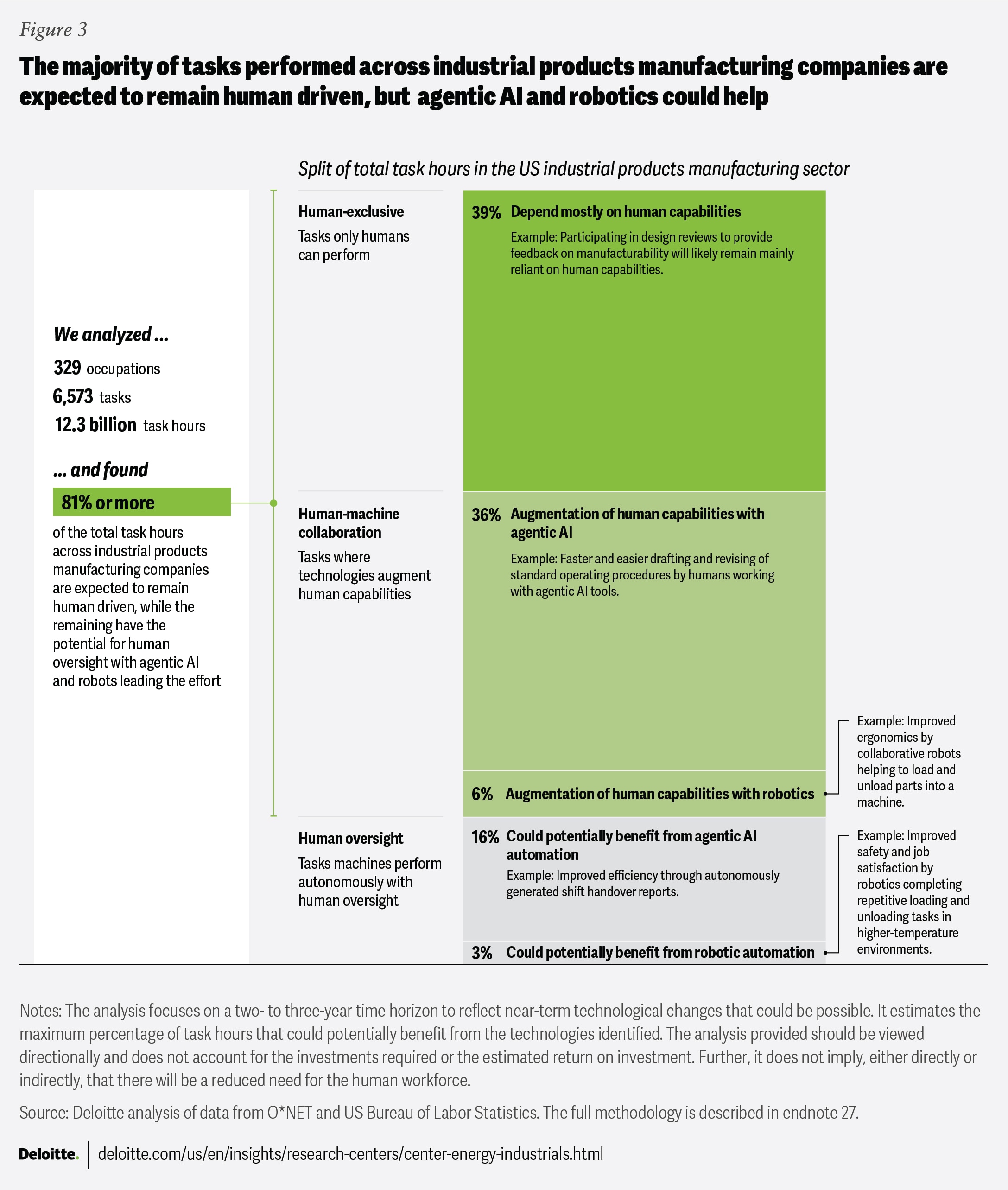

Change management is also important. According to a recent Deloitte report, organizations that invest in building human capabilities are almost twice as likely to have employees who find their work meaningful and to achieve superior business outcomes.25 Implementation of agentic AI solutions is likely to alter workflows, decision-making processes, worker roles and skill requirements, and potentially organizational culture. Yet according to Deloitte’s analysis, 81% or more of task hours across the industrial manufacturing sector26 are likely to remain human driven (figure 3, the full methodology is described in the endnotes),27 emphasizing the need for a continued strategic focus on both technical and human capabilities.28 Additionally, as AI automates routine tasks, roles are likely to increasingly emphasize the need for creativity, collaboration, emotional intelligence, and problem-solving—skills that are uniquely human—and new roles could be created.29

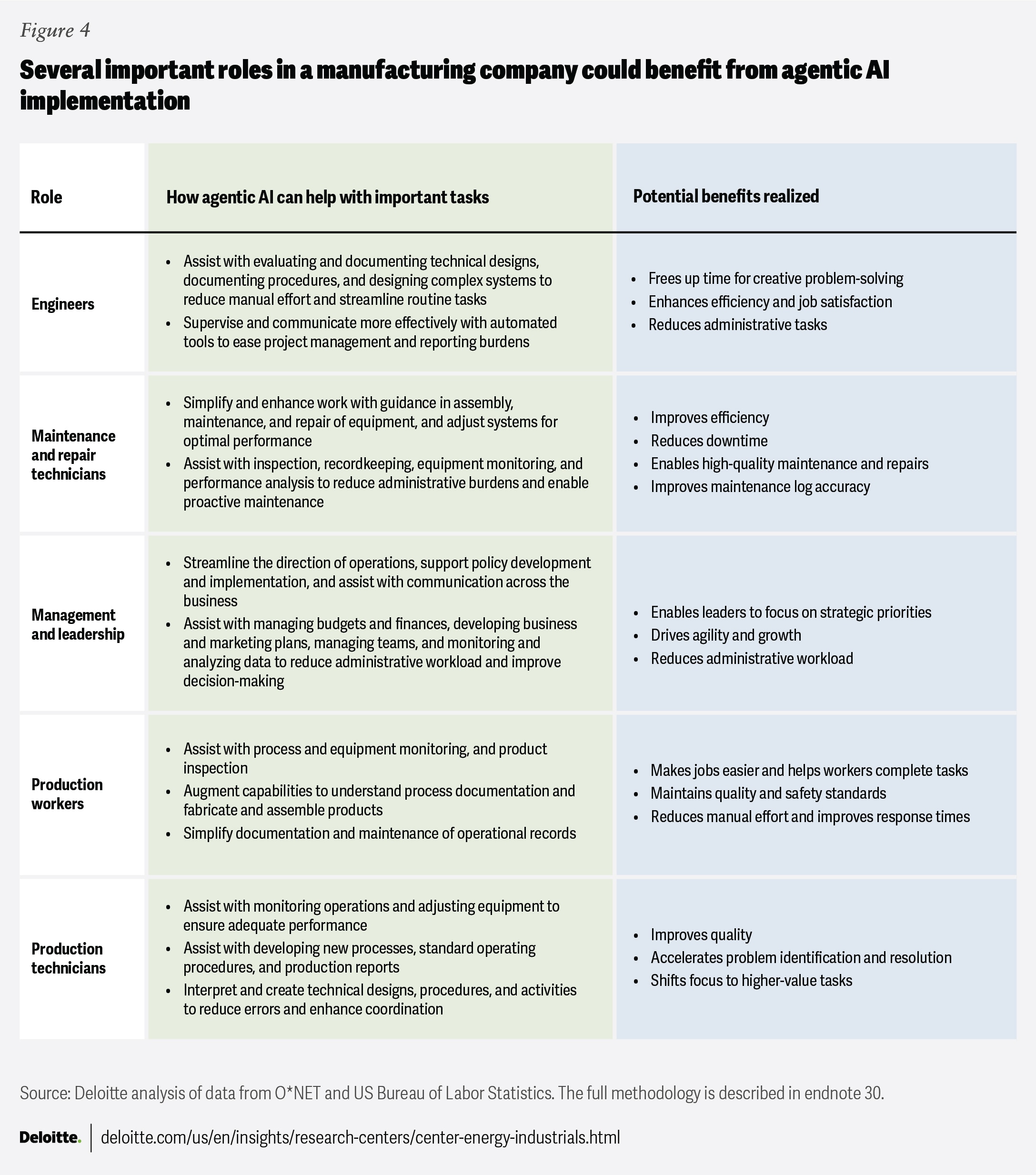

Proactive communication, targeted training, a collaborative adoption approach, and ongoing support may be essential to help employees adapt. For instance, active communication about how agentic AI could positively impact some of the important roles in the organization (figure 4, the full methodology is described in the endnotes)30 may help cultivate worker interest in the technology, and potentially accelerate its adoption. Leaders should foster a culture of continuous learning and innovation, encouraging teams to embrace change. Some organizations are already moving in this direction. For example, nearly 80% of surveyed employers in the World Economic Forum’s "Future of jobs report 2025" are planning to prioritize reskilling and upskilling their workforce to enhance collaboration with AI systems by 2030.31

Implement pilots with prioritized opportunities and stakeholders

With the technical and organizational foundations in place, manufacturers can proceed to implement pilots focused on the highest-priority opportunities identified in the road map. Unlike traditional technology rollouts—where multiple pilots are often conducted across a wide variety of business functions to identify the most promising use cases—the agentic AI approach is more targeted. The road map has already pinpointed the solutions with the greatest potential to deliver value at scale within specific business domains, such as engineering or aftermarket services. Multiple pilots, such as agentic parts ordering and agentic step-by-step repair guidance, can be conducted within these domains to demonstrate proof of concept, refine the solution, and build confidence among stakeholders. These pilots should be designed to test not only technical feasibility but also business impact, user adoption, and integration with existing processes.

Taking this approach enables organizations to demonstrate value and address critical technical and operational transformation challenges, positioning them to capture near-term benefits and significantly increase the likelihood of success at scale.32 Each pilot and subsequent scale-up provides valuable insights that can be leveraged to refine strategies, address challenges, and accelerate adoption across the organization. Building on the momentum of successful pilots, companies can continue advancing along the agentic AI road map toward enterprisewide transformation.

The road ahead

Agentic AI solutions are poised to deliver transformational value across the manufacturing industry by fundamentally changing how companies run their businesses. Adopting agentic AI is not just about automating tasks. It’s about solutions to industry challenges that may have seemed unimaginable just a few years ago, that are now available with AI. However, there are challenges to overcome. Fundamental changes to data management and workflows could be necessary to maximize the value of AI agents working with people as teammates. Establishing governance, rethinking how work gets done, managing organizational change, and building human capabilities will be important to ensure trust in the partnership between human and machine, and the outputs they can produce in concert.

Manufacturers that can capture the potential value of agentic AI likely stand to gain a significant competitive advantage. A structured and disciplined approach—and one that is different from what is traditionally used for technology adoption—may be what is necessary to get there.