From one to many

Scaling the smart factory to a smart network

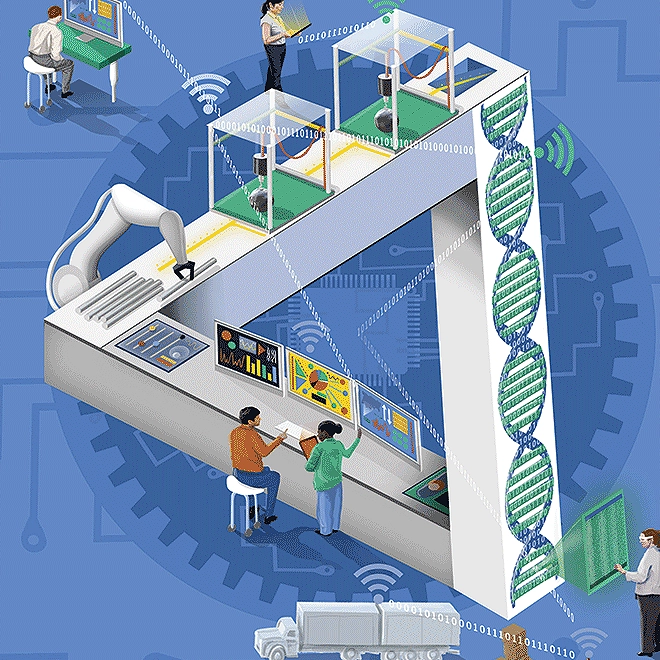

With supply chains under unprecedented stress, companies are looking to scale smart manufacturing systems across locations. A network of smart factories can improve efficiencies and toplines—and drive competitiveness.

Introduction

FIRST, a real-life case example. Amid global demand softening and heightened competition, a heavy equipment manufacturer was looking for ways to drive operational improvements. The company implemented smart factory solutions across its plants in two phases. Phase 1 improved visibility on the shop floor through an asset tracking system (GPS and RFID sensors) to identify turnaround time variances between planned and actual times. Real-time dashboards enabled production managers to identify schedule delays and quality issues, leading to annual savings of about US$1 million just from one production line.1 The solution was subsequently scaled to other plants as well. Phase 1 implementation made assembly line outputs streamlined and predictable, thereby optimizing transportation of goods to dealerships in phase 2. With live tracking, pickup and delivery operations were synced to actual production, thereby reducing the cost of holding inventory at the shipyard, increasing the load factor for each shipment, and improving dealer satisfaction. Overall, the company was able to ring in annual savings of US$5 million to US$7 million across four plants where smart factory solutions were scaled.2

By investing timely in the right digital capabilities, cloud services, connectivity, and digital skills, companies could be better positioned to navigate challenging times such as these and can, as such, accelerate their digital journeys because of the benefits realized.3

The COVID-19 pandemic has put unprecedented stress on global economies and highlighted as perhaps never before the importance of maintaining an agile supply chain and efficient manufacturing operations. Smart manufacturing systems, including industrial IoT, can play a larger role in the months and years ahead, offering organizations the ability to use their digital footprint to manage labor/absenteeism risks, production scheduling complexities, and upstream and downstream supply chain risks.

By scaling smart factories across locations, manufacturers can adjust their production processes and product mixes to the volatile supply-demand drivers among plants. A network of smart factories could drive organizations’ overall competitiveness in the form of improved efficiencies and toplines—competitiveness that could be critical in the tough economic environment ahead.

The benefits of harnessing smart factory capabilities across digital supply networks can be significant, and organizations typically start small, create proof-of-value projects, and then aim to quickly scale across their factory network once the concept has demonstrated value. Starting small is a time-tested approach to success, but many companies run the risk of starting too small. This can make it challenging to scale these initial solutions more broadly to other facilities because each factory has its own operational processes, culture, technologies, and key performance indicators (KPIs) to measure value creation and success. Most often, companies end up implementing discrete smart factory solutions in pockets within the organization (we call it “random acts of digital”), thus limiting the value realized by the solution(s).4

So how can companies move from a single smart factory implementation to a holistic, enterprisewide implementation—to which we refer as a smart network—while considering some of the local characteristics of the factory? In other words, how can companies scale globally, and execute locally, all the while minimizing disruption and the overall cost of ownership? In this article, we discuss:

- Challenges associated with scaling smart factory solutions

- Implementation components and techniques to address the challenges and lead to scaled adoption of the solution

- Considerations to keep the scale successful

Defining the smart factory

The smart factory is a flexible system that can self-optimize performance across a broader network, self-adapt to and learn from new conditions in real or near-real time, and autonomously run entire production processes.5 Broadly, a smart factory has five key characteristics:

- Connected processes, materials, and equipment

- Optimized for minimal manual intervention and high reliability

- Transparent network to enable greater visibility across the facility

- Proactive approach for issue identification and troubleshooting

- Agile operations to self-configure equipment and material flows with staffing, schedule, and product changes

These smart factory characteristics, together, enable manufacturers to stay resilient and adjust and adapt their manufacturing and supply chains for external exigencies.6

What's holding companies back?

It is often challenging to scale smart factory solutions, including IoT technologies, more broadly across the network, for generally four reasons:7

- Business model and operations challenges. Local processes across plants may vary depending on production operations and product mixes, making it challenging for business teams to scale up implementations across the network. Also, business value can be measured in different ways across different parts or locations in a company; for instance, overall equipment effectiveness (OEE) may be calculated differently across plants and locations, leading to the local rejection of a globally scaled effort. Most importantly, considering different processes, measures of value, and cultures, organizing a program structure can be challenging. The structure involves multiple stakeholders—corporate and plant leadership, continuous improvement teams, plant IT, plant operations, quality control, and others—and should include joint sponsorship at both corporate and plant level.8

- Technological challenges. Existing technology infrastructure—including production equipment, IT networks, operations technology (OT) infrastructure, security protocols, data models, and architecture—may vary by location and plant and are potentially aged beyond their useful life. By starting with a point solution, technology teams often fail to anticipate the generalities needed to reproduce the solution architecture at a broader scale. This can lead to needless builds and teardowns.

- Talent and leadership challenges. Along with the business and technological differences across a network, talent landscape also includes different types of job roles, skill sets, and cultures that need to be considered when scaling a solution. Furthermore, while such solutions tend to be piloted in facilities with strong leadership support, scaling requires engaging with leadership that may be uncomfortable with new ways of working, and skeptical of anything that could disrupt day-to-day operations and increase visibility outside of the “four walls” of the factory.

- Data management challenges. Managing and utilizing data from multiple sources within a smart factory is tricky; managing data across plants is even more difficult. The most profound challenge, though, results from the lack of data availability from legacy equipment, since the average life of manufacturing equipment in the United States is more than 20 years.9 Many engineers typically spend 30% to 70% of their time gathering information from legacy systems and manually copying in spreadsheets.10 Challenges also relate to optimal processes for collection, storage, management, protection, and governance of huge and diverse data sets and, more importantly, using this data for business outcomes related to plant operations, productivity, and bottom-line improvements at scale.

Getting started with scaling

Scaling of smart factory solutions should be driven by a North Star: a common purpose, and a strong focus on value that is well-defined.

In this section, we discuss the journey to scale a smart factory and its many different components or stages (figure 1): enterprisewide vision and alignment, program structure, planning and templatizing, execution to scale, deployment, and postdeployment support. The connective tissue across these components includes program governance and talent and data management, which play key roles all along.11

Enterprisewide vision and alignment

Enterprise vision and network alignment should always maintain a focus on value to drive successful scaling. Once a proof-of-value project proves successful, it is prudent to expand the smart factory vision based on a holistic view of operations across locations aimed at both digitizing manufacturing and achieving operational synergies (value) in the process. To drive alignment, especially if the enterprise is large and manufactures multiple product categories, leaders could group the smart network into plant archetypes based on a multitude of factors, such as manufacturing type, asset commonality, velocity and volume considerations, and management organization.

The leadership should standardize KPI definitions across the organization so that there is alignment to a common purpose for value creation.12 With corporate leadership’s laser focus on value, having a baseline of KPIs at the corporate level enables a consistent measurement of value and a standardized comparison of plant performance. It also helps with identification of plants and areas within plants to start the implementation and have a regular review of KPIs to determine the value that is created at both plant and corporate levels.

Many technical and execution challenges may not surface during the proof-of-value phase. However, when planning for the program scale, the vision statement should drive a detailed road map that takes into consideration new issues that may surface, such as cultural differences, planning for data ingestion volume, application performance characteristics, and configurability of the solution.

Program structure

Strong program structure is critical for decision-making and for executing the decisions to scale the smart factory successfully. Given the multiple stakeholders involved at both the corporate level (operations, supply chain, strategy functions) and the plant level (plant managers, engineers, operators, technicians), a regular engagement with all the relevant stakeholders is important.

Organizations should establish a dedicated digital manufacturing group (DMG) that drives consistency across the organization through centralized focus on processes and operations while also accounting for local nuances across plants and reporting the progress back to the leadership and reviewing value achievement over time. In one example, a large food packaging manufacturer established a dedicated DMG organization with a federated structure: The centralized organization was at headquarters and resources from the plants (especially continuous improvement) represented their plants in the centralized governing body.13 The federated model ensured alignment at the macro level while empowering the local plant operations to determine execution-level decisions. Leaders embraced this model, and it soon became a strong ally for the operations team across the board.

Finally, a networkwide communication mechanism within program structure could provide clear expectations and milestones of each iteration, closed-loop feedback to measure effectiveness as the program scales, and broadcast status of the program across locations to inform and energize stakeholders in the long scaling journey.

Planning and templatizing

In addition to target state definition and gap analysis, defined software development processes and standards that are based on an iterative model allow for incremental development of the solution in an otherwise-fragmented ecosystem. Cross-plant operational technology (OT) and IT process templates keep the many moving parts of the program in sync. The replication team should create timelines for solution rollout that includes most plants and map out overlapping timelines for sharing of leading practices. The timelines should include a checklist of dependencies and prerequisites to templatize the solution. Throughout these efforts, security considerations should be built in the design and build phase itself.14

Scaling the solution should also require grouping of plants based on characteristics, including:

Use case identification. The first step in planning is to understand the current state of infrastructure maturity at each plant and perform a gap analysis on what it takes to get to the target state. Plotting the identified use cases based on readiness and grouping strategically interrelated use cases for collective roll-out is recommended for effective scaling. Both objective (value-driven) and subjective (enterprise dynamics and culture) criteria drive the identification of use cases. Once the use cases are identified, the next step is determining which assets to fold into the solution. While it may be cost-effective to focus on similar assets, the solution becomes complete and more robust by piloting the solution to different types of assets.15

DevOps environment management. DevOps strategy aims to bridge the gap between the development team (developers, testers building the code) and operations team (deploying the code to production) to improve technology implementation.16 Depending on the solution maturity from low to high, environment infrastructure could be considered plant by plant versus centralized DevOps environment strategy. Source code control and management practices should be employed to keep a single version of the code base deployed across the solution. And in replicating to multiple locations, it is important to keep location-specific enhancements to a minimum and, when required, to keep the customized code separated from the general code base.

Test and release strategies. Additional efforts include a thorough and nonrushed test strategy (including functional testing, automated regression testing, and performance testing) and releasing management capabilities across the network of plants. Testing costs can be contained by carefully executing test environment strategies where with each plant rollout, a new set of plant specific test environments are not required. This strategy is best formulated and executed in concert with the product team who is defining the product features and rollout cadence. It is prudent to set expectations with the team on the impact of test strategy and test environment decisions made jointly and what that can mean for end-user experience on the plant floor. How testing and release management is implemented while executing with speed and at scale is a balancing act between cost, user experience, and quality, and requires a careful and well-thought-out approach.

Change management and adoption. A centralized change management team can support the scalable smart factory solution by providing cultural awareness and workforce training across locations. Solution adoption can generally be best executed when the end-users themselves are eager to use the solution. Change management teams can act as a bridge between end-users and the product team by funneling end-user feedback and requests in the product road map to enhance relevance of features and boost solution adoption. Further, change management teams should understand the solution thoroughly and provide continuous training and support on the shop floor to address any questions workers may have before, during, and after an implementation. Overall, a seamless user experience and near real-time support is important to maintain end-user interest and adoption of the solution.

Infrastructure management. Asset management of all IT and OT systems, along with patch-level information for each asset, is important to ensure that the system can be brought back to function in case of solution component failures. Further, a disaster recovery plan that is in place at both the plant and central level can bring the solution back to a fully operational state in case of a catastrophic event—physical or cyber—that could involve bringing back people into the plant or resetting data systems from scratch. A homogenous infrastructure across the network also yields benefits such as economies of scale, sharing lessons learned across the enterprise, and operational efficiencies, to name a few.

Execution to scale

Execution is based on a scalable architecture that can adapt to the multiple plant archetypes considering elements related to product mix, operational characteristics, infrastructure, application, and data management, with security considerations associated with each element. A scalable architecture can accommodate loosely coupled systems through use of application program interfaces and adapters and helps drive a cohesive data model built on foundational pillars of standards compliance, security, and usability. The true value of industrial IoT shines through when sensor data is decorated with contextual information—for example, adding manufacturing execution systems' (MES) information to location coordinates and time series can drive insights on takt times for a particular order in discreet manufacturing. While the baseline for the architecture could be designed during the proof-of-value phase, the actual architecture is live as it evolves with the growing footprint of the business’s solution and needs.17

Successful execution hinges on a frictionless coordination between the various workstreams consistently across plants. For example, functional teams should be aligned on the capabilities that need to be built: IT/OT should focus on unlocking value with minimal complications and developers, and quality assurance should be provided very clear implementation-level requirements. Program management, both plant and corporate, should be tightly coordinated with plant IT and vendors, to ensure that the correct resources are available to build the solution.

In addition to the technology execution, building trust across the organization is often crucial during the execution phase. Once the new processes are in place, it’s important to thoughtfully enable data-driven automation based on newly available sources of data. Leaders can build trust in the digital transformation journey and the smart manufacturing/smart factory IoT solution by following the three stages of digital maturity, through incremental changes depending on plant maturity from simple to complex applications:

- Using technology to provide greater visibility to the technicians (implemented consistently across plants)

- Installing smart alert systems that prompt manual corrective action (implemented somewhat consistently across plants based on presence of smart systems), and

- Deploying algorithm-driven corrective actions (implemented variably depending on plant maturity)

Overall, a successful execution at scale involves a number of elements that balance each other and keeps the network in equilibrium (figure 2). A clear statement of the business value to be derived from the effort, along with a strong alignment to business strategy, can help ensure that the scaled plants are up and running in time. A detailed mapping of business processes and preparation for the accompanying technical complexity involved and workforce skill requirements can help enable an effective implementation of solutions. A rich user experience can ensure that change management techniques work on the shop floor and that the network of plants is ready for the potential impact of unexpected events.18

Deployment

Deployment of the smart network is a multistep process, beginning with turning on the data flow from the sensors, configuring the application to receive the data, and then tuning the dashboards to display meaningful and accurate information. Leaders should carefully review the plan to deploy the code and algorithms from one plant environment to another to eliminate potential errors in the deployment process. Checks should be baked in the deployment process at each step to ensure that deployment components in each layer (including OT) of the solution have been configured properly and are working as expected. Lack of rigorous discipline can be catastrophic, including corruption of existing data and potentially losing access to the application for extended periods of time.

One of the ways to mitigate potential errors resulting from manual deployment is to make use of automated deployment tools. However, creating automated deployment scripts typically requires a thorough testing of the deployment steps, checking results in the intermediate steps, and baking in rollback steps in case the deployment needs to be aborted at one or more plants. Such scenarios make automated deployments complex and require a certain degree of maturity of the solution and automation skill sets.

Postdeployment support

During this phase, it is critical to manage the end-user experience, as any unaddressed issues can cause rejection from the user community. Rejection could result from several reasons, including heterogeneity of applications/screens, production processes, and cultures and tech openness/readiness across plants—factors that are often considered critical in the post-deployment phase. Additionally, once the application has been deployed, it should be constantly monitored for performance issues that may arise in the production environment.

Postdeployment support should be multitiered and employ knowledgeable resources, tasked centrally, to train and provide support to the local IT teams. This is also the time for a changing of the guards in which plant IT resources should ramp up and be the front line of support for users in the plant to ensure timely troubleshooting to deliver per common program timelines and ensure smooth scaling. Corporate and plant stakeholders should regularly evaluate the solution adoption across plants vis-à-vis the plan and review bugs to ensure there is no slowdown in adoption and that users continue to use the system as planned.

Focusing on the connective tissue

As figure 1 shows, through each of the scaling components from enterprisewide vision to post-deployment, program governance and talent and data management play a pivotal role.

Program governance. A complex and multiyear program requires governance from corporate leadership, beginning with an organizationwide strategy to providing effective deployment support to ensure a smooth scale.19 Besides setting the tone of the program across the board, top-down engagement ensures speed of execution, timely decision-making, and above all, resources and finances required to sustain the program.

In the manufacturer example, effective program governance led to the smart factory scaling from a single assembly line to multiple plants in the United States and globally. By correctly identifying the plant archetypes and alignment on performance measurement in the governance model, leaders addressed the issue of operational visibility. By bootstrapping capabilities across the network, there was a sense of “winning” across the enterprise, which boosted momentum at the grassroots level. The board approved subsequent phases and the multiyear scaling program continued with tangible results.20

Talent management. Two aspects are particularly pertinent for talent: user interface/experience with the new solution and workforce skill sets. First, user interface/experience should make work easier for shop floor employees and help them deliver measurable success on centralized KPIs.21 Second, when the smart factory is scaled, it could require new skills (for design, delivery, and postdelivery), expansion in existing roles, or new roles altogether. While some training programs for program initiation can be consistent across plants, others could be tailored to location needs based on skills available and operational process maturity. Training teams should instill a growth mindset22 and make smart factory a part of how business is done throughout the enterprise so that standard work, procedures, and policies can be updated to support new smart factory–enabled processes.

Data management. While scaling the smart factory, it can be challenging to aggregate and integrate data coming from several legacy platforms across plants.23 By developing a common data model early at the program structure stage, integration issues can be minimized as the solution begins to scale with extensive deployment. It’s important to have a strong data governance body that publishes enterprise guidelines, procedures, and timely approval for data creation, storage (on-premise or cloud), and use of data.24 Further, half of manufacturers have faced a cyberattack at some point, making it crucial to plan a comprehensive cybersecurity strategy when implementing an enterprisewide solution rollout.25

Implementing digital manufacturing

The food packaging manufacturer described earlier was facing capacity constraints, OEE at 68%, and plant downtime, risking the loss of millions of dollars in potential revenue and missed margins. The company started with adding IoT sensors to one production line to collect data and improve visibility into machine performance, and to track sources of variation and downtime.26 Early returns manifested in the form of improved OEE with existing assets and labor.

Through IT and OT connectivity, process redesign, and change management, the company rolled out asset intelligence capabilities across all factory lines within the plant. By establishing a DMG, the leadership supported culture and process changes to make full use of the new application, and employed the asset intelligence systems across multiple plants through a multiphase, multiyear journey. The persona-based application (operations manager, line supervisor, operator etc.) ensured that the right information was available to the right role at the right time, making the intended individuals’ tasks intuitive.

Results from the transformation included 9% OEE improvement across the network within three months of the implementation, capital expenditure savings of more than US$24 million by unlocking capacity of existing assets, and incremental revenue of close to US$50 million.27

Keeping it up and running

Once the smart factory is scaled to multiple plants, organizations should turn their focus to longer-term business imperatives. Leaders should focus on key areas to keep the scaled operations running and successful in the long run as talent and tech readiness mature and organizational needs evolve:

Leadership involvement. Senior leadership should be the driving force behind sustained adoption of the solution for newer plants coming into the fold with support from all stakeholders including the corporate DMG, plant-level digital manufacturing teams, and plant administration teams.28 While considering plant nuances, incentives and rewards should be aligned from the top floor to the shop floor so that the execution remains focused on the North Star.

Communication management. In the absence of clear communication about the scaling program, there may be a perception on the shop floor that the technology is intended to reduce headcount, resulting in anxiety and resistance to change. At the beginning of the program, the DMG could craft a communication for all the plants describing the benefits of the proof-of-value implementation and the plan for scaling. Throughout the scaling journey, there should be regular messaging from the leadership about the program’s progress and how it is helping at the enterprise, plant, and individual levels.

Funding support. Keeping the smart factory program funded, especially when trying to scale, may be difficult, primarily due to the incremental nature of benefits realization that can be spread across multiple organizational divisions. Creative funding strategies include reinvesting program benefits and R&D tax credits back into the central program, creating a central special projects’ pool of funds, and leveraging vendor partnerships for cofunding at the plant level.

Business continuity. To ensure that the project retains the trust gained during the proof-of-value phase while scaling, the program should prevent and limit any operational disruptions on the shop floor, with lessons learned from one plant shared and implemented to other plants. The deployment team should coordinate to limit any planned down times needed for hardware installations or deployments during operation hours. The DMG should actively track operational risks that could cause potential disruptions. Additionally, leaders should look to ensure business continuity by updating and refreshing service agreements with vendors and supply chain partners across plants in line with the new requirements.

Overall, the program should strive to make the digital solution adoption, management, and maintenance a part of the organization’s DNA.

It’s a marathon, not a sprint

Smart factory implementations present opportunities for operational improvements as well as top-line growth, and these benefits naturally compound with scaling to multiple plants. Use case selection for the proof-of-value development should be carefully curated to accelerate value realization, as it helps establish credibility of the program and plays a pivotal role in charting the success of the effort at the enterprise level.

It’s OK to start small but important to scale quickly from initial successes. As organizations move forward in their journey from a smart factory to a smart network, there are challenges and hurdles that will need to be addressed early in the process, to control costs and improve speed to market. Fortunately, there are time-tested strategies that companies can consider for their scaling efforts and customize based on business needs and organizational and people readiness.

More importantly, as digital transformation is a continuous process and digital maturity is an evolving target, leaders should employ progressive and simple wins in the journey to inspire the workforce. The scaling journey is complex and typically requires executive sponsorship, relentless focus, and grassroots support to be successful. The program should be value-led, technology-enabled, and people-centric to enable the enterprise to realize its full potential and build a successful business prepared for external exigencies.

Supply Chain & Network Operations (Digital Supply Networks)

The US Supply Chain & Network Operations practice advises, implements, and operates transformational solutions that bring world-class supply network capabilities, operational know-how, digital technologies, and advanced analytics to deliver unprecedented client value.